Process

Taking Wood from Backyards to the Mill - and Back Again

The path a tree takes from standing in a yard to being turned into a table or garden bed has several steps. Explore the steps below to get a sense of how a tree transitions from growing on a property to becoming finished product.

Tree Removal

From Tree to Logs & Woodchips

Tree removal in urban settings has been around a long time. However, purposefully harvesting usable lumber from these removals is relatively new. Not every tree removal produces a mill-able log, but many do. We aim to use those mill logs to their fullest potential, giving them a second life as lumber, furniture or backyard structures.

After we remove trees from a client property, we sort out the wood into shorter pieces and suitable mill logs. Shorter pieces and wood otherwise unsuitable for milling are loaded into a trailer and brought to various sites to be turned into landscape mulch.

We sort millable logs into either two categories, either bolt wood or Heartwood Projects logs. The bolt wood is hauled away by the semi load by Meister’s in Endeavor, WI, where they mill and dry the wood to be turned into food-grade pallets. Heartwood Projects logs go to a farm we rent in Oregon, WI for milling, stacking, and drying (see below).

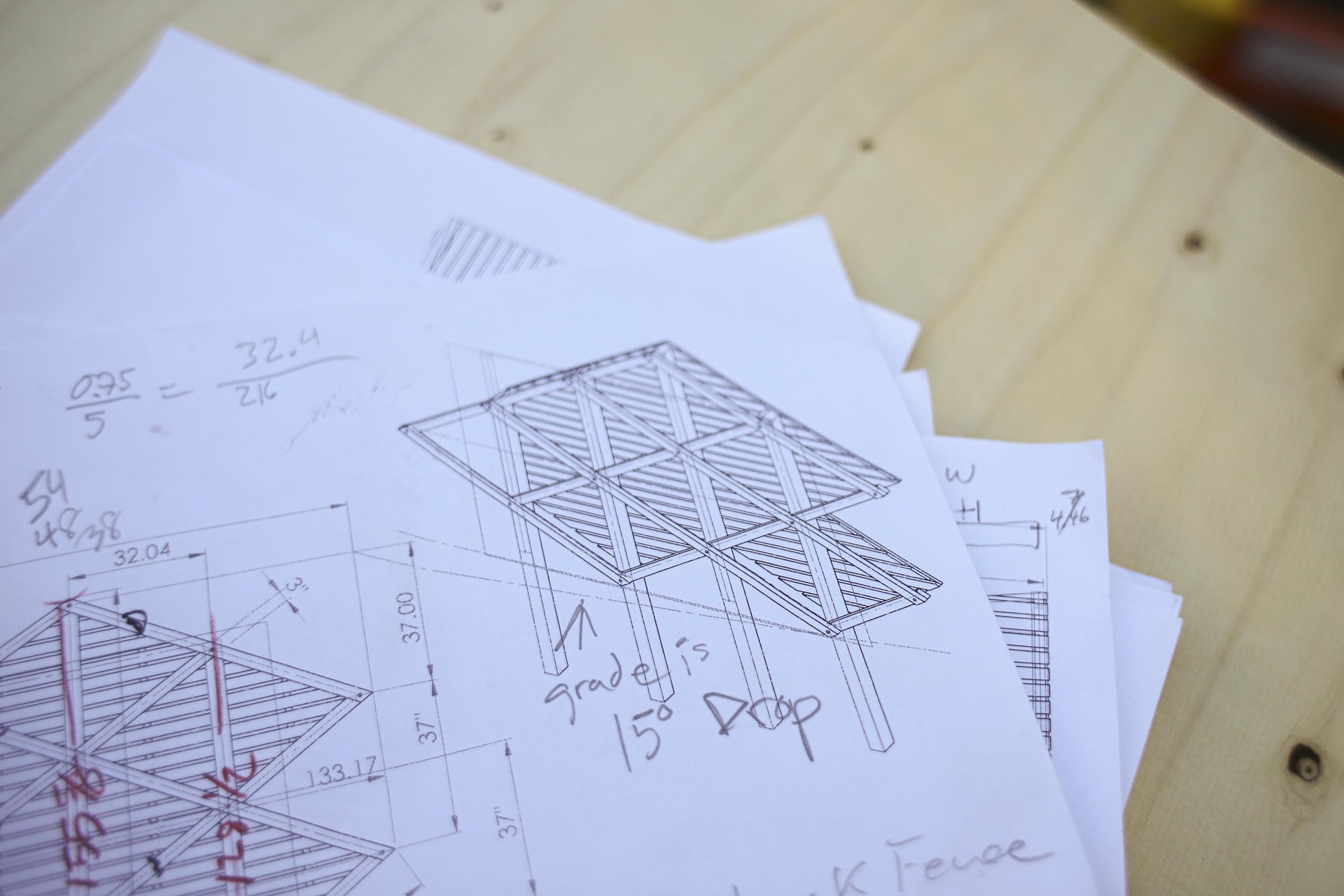

Design

Developing a Vision for a Felled Log

Once we have a log on the ground, we can start the design process. We are able to better determine potential products that can be made from the tree when it is laying on the ground, cut into sections, as features reveal themselves that were hidden when the tree was standing. For example, a solid-looking trunk may actually be hollow inside. Or a log may be too large to remove from a tight space, or too heavy for our equipment.

The design process will dictate how we mill the log, making sure the cuts will yield the necessary components for the finished product. As a basic example, we would leave the edges of the tree on the wood for a live edge piece, but not for wood paneling. More intricate examples might involve milling a trunk to feature a branch union with unique figuring, or wood grain for a desk top or bench.

The inspiration in the design process can be as simple as a client browsing our past projects or a client wanting to take on a new commission.

Milling

From Tree Trunk to Lumber

We generally hire local sawyers with portable mills to help us turn felled logs into usable lumber. These sawyers visit our mill log lot, where they set up their saw mills and cut our tree trunks per our requests. They are pretty amazing technicians, it’s fun to watch.

Types of Milling

Milling itself can take two main forms, producing either slabs or dimensional lumber.

Slabs

The first type of milling is slabbing the log into wide, thick boards, or slabs, with bark and the natural edge on two sides. This type of milling is most often used for live edge tables, benches, and shelving.

Dimensional Lumber

The second form of milling is creating dimensional lumber. In this approach, all the bark and natural edges are removed to produce a cant. A cant is essentially the log turned into a rectangle or square. Once we have a cant, the mill then starts to cut dimensional lumber according to desired specifications.

We utilize both slab and dimensional methods, with an emphasis on dimensional lumber. If your project is destined for the indoors we will take the additional step of kiln drying the lumber.

We utilize both slab and dimensional methods, with an emphasis on dimensional lumber. Once wood of either type is milled, it is then stacked to air dry in our lumber yard.

Kiln Drying

If your project is destined for the indoors we will take the additional step of kiln drying the lumber. The kiln drying process heats the wood enough to kill off any bugs living within. It also dries out the wood so it moves and shrinks less after it is installed inside a home or building.

Build

Translating Plans into Reality

This is where the action really starts to pick up. The design is set, the logs have been milled, lumber dried, and now the sawdust starts to fly. This is the fun part where we lean into our decades of wood working experience to carry out the design.

Delivery & Installation

From Our Shop to Your Home

The last step in the journey is delivery and installation. This is the moment we have all been waiting for - seeing your tree returned to you.

We encourage you to dream big when thinking about how your tree could live on in your home, office or backyard. For more ideas and inspiration from our past projects, explore our Commission pages.